What is a Single Row Bearing?

Bearings are indispensable components in various machinery and mechanical systems, serving the crucial function of reducing friction and facilitating smooth rotation or linear movement. Among the many types of bearings available, the single row bearing is a fundamental and widely used variety. In this article, we will explore what a single row bearing is, its design characteristics, and its common applications.

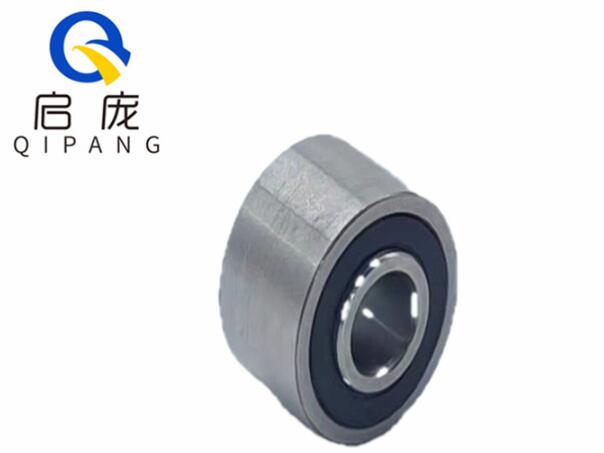

Understanding Single Row Bearings

Single row bearings, also known as deep groove ball bearings, are a type of rolling-element bearing. They are named "single row" because they consist of a single row of balls (rolling elements) that run in a continuous groove in both the inner and outer rings of the bearing. This design allows for axial and radial loads to be supported simultaneously, making them versatile and suitable for various applications.

Design Characteristics of Single Row Bearings

Single row bearings possess several design characteristics that make them distinct and functional. These characteristics contribute to their wide range of applications and popularity in various industries:

1. Inner and Outer Rings:

Single row bearings have an inner ring that fits onto a shaft and an outer ring that fits into a housing.

2. Ball Cage:

The balls within a single row bearing are held in place by a ball cage, which ensures even spacing and prevents contact between the balls, reducing friction and wear.

3. Groove Configuration:

The groove in both the inner and outer rings is typically deep and continuous, allowing for the smooth rotation of the balls.

4. Radial and Axial Load Capacity:

Single row bearings are capable of supporting both radial loads (perpendicular to the shaft) and axial loads (parallel to the shaft) to varying degrees, depending on their design and size.

5. Lubrication:

Proper lubrication is essential for the long-term performance of single row bearings. They can be lubricated with grease or oil, depending on the application and operating conditions.

Common Applications of Single Row Bearings

Single row bearings are highly versatile and find application in a wide range of industries and machinery. Here are some common applications where single row bearings are frequently used:

1. Automotive Industry:

Single row bearings are found in various automotive components, including wheel hubs, transmissions, and engine components. They provide smooth and reliable rotational movement in these critical systems.

2. Electric Motors:

Electric motors in appliances, industrial machinery, and HVAC systems often rely on single row bearings to support the motor shaft, ensuring efficient and low-friction operation.

3. Agricultural Machinery:

Agricultural equipment such as tractors, combines, and harvesters use single row bearings in various components, including wheels, drive systems, and conveyors.

4. Industrial Equipment:

Single row bearings are integral in conveyor systems, pumps, compressors, and various industrial machinery, where they support shafts and reduce friction in rotating components.

5. Household Appliances:

Common household appliances like washing machines, refrigerators, and blenders utilize single row bearings in motor assemblies and other moving parts.

6. Power Tools:

Power tools, including drills, saws, and grinders, often rely on single row bearings to provide smooth and precise movement in rotating components.

7. Aerospace Industry:

In aircraft and aerospace applications, single row bearings play a role in various systems, including landing gear, control surfaces, and engine components.

Selecting the Right Single Row Bearing Supplier

When choosing single row bearings for your specific application, it is essential to partner with a reliable bearing supplier. A reputable supplier can provide:

Expert Guidance: Knowledgeable professionals who can assist you in selecting the right type and size of single row bearing for your application.

Quality Products: High-quality single row bearings that meet industry standards and performance requirements.

Customization: If your application requires specialized bearings, a trusted supplier should be able to provide customized solutions to meet your unique needs.

Technical Support: Responsive technical support and assistance with installation and troubleshooting.

In conclusion, single row bearings, also known as deep groove ball bearings, are essential components in a wide range of machinery and mechanical systems. Their design characteristics, such as the continuous groove and versatile load-bearing capabilities, make them invaluable in various industries. If you have questions about single row bearings or need assistance in selecting the right bearings for your application, please don't hesitate to contact us. Our team of experts is ready to help you find the perfect solution for your bearing needs.

评论

发表评论